Key Advantages of Using a Membrane Switch in Industrial Applications

Key Advantages of Using a Membrane Switch in Industrial Applications

Blog Article

Recognizing the Functionality of Membrane Changes for User Interface Devices

The functionality of membrane layer switches over represents a substantial advancement in individual interface layout, combining effectiveness with aesthetic flexibility. As sectors increasingly prioritize customer experience, understanding the nuances of membrane layer button modern technology ends up being crucial.

What Are Membrane Switches?

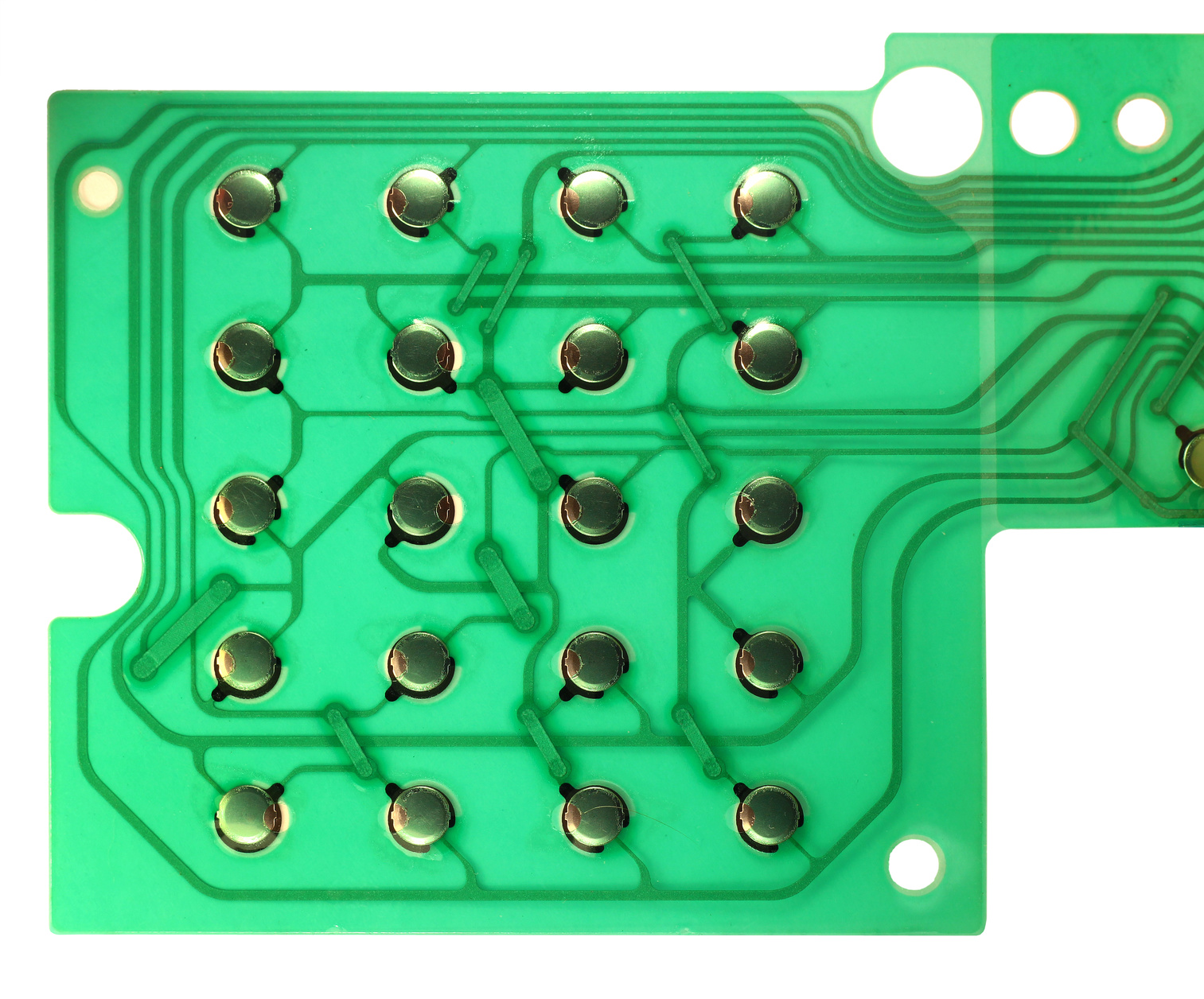

Membrane layer switches are innovative interface gadgets that promote user interaction with electronic devices. These functional parts are composed of multiple layers, including a visuals overlay, spacer, and a published circuit layer. The style enables a seamless integration into different digital tools, enhancing both the aesthetic and functional aspects of user interfaces.

Membrane switches are commonly employed in a large range of applications, from home devices to industrial equipment and medical gadgets. Their construction generally features a thin account, making them an excellent option for portable styles. The tactile feedback offered by these buttons can be crafted to fulfill certain individual preferences, guaranteeing effective interaction in between the user and the device.

Durability is an additional considerable advantage of membrane layer buttons, as they are resistant to dirt, dampness, and chemicals, which improves their life-span popular settings. Additionally, these buttons can be personalized in regards to form, size, and visuals style, allowing for branding and user-specific features. Generally, membrane layer switches over stand for a functional remedy for enhancing customer experience in electronic devices, combining functionality with aesthetic appeal in an efficient fashion.

Exactly How Membrane Switches Work

Operating on an uncomplicated concept, membrane layer switches over make use of a split building to sign up user input effectively. Each switch is composed of several layers, including a published circuit layer, a spacer layer, and a leading graphic layer, which are made to collaborate perfectly. When a customer presses the top layer, it presses the spacer layer, bringing the conductive components of the circuit layer into contact with each other.

This contact creates a closed circuit, signifying the tool to implement a particular feature. The design allows for various arrangements, including responsive comments, which can boost the customer experience by providing a physical sensation upon activation. The products used in membrane layer switches usually include flexible substrates, such as polyester or polycarbonate, which guarantee toughness and resilience against wear and tear.

Trick Benefits of Membrane Layer Switches

One more substantial benefit is their density. Membrane layer switches are slim and lightweight, which makes it possible for producers to save room in their tools without compromising performance. This feature is specifically helpful in applications where weight and volume are critical factors to consider.

In addition, membrane buttons are resistant to dirt, wetness, and chemicals, boosting their toughness. This resilience prolongs their life-span and decreases the need for constant substitutes, causing cost financial savings in time.

Furthermore, the responsive comments supplied by membrane buttons can be maximized to improve customer interaction. They can include features such as increased buttons or distinct clicks, improving functionality and user experience.

Applications Across Industries

Customer interface tools making use of membrane switches are prevalent in a large range of industries, showcasing their versatility and capability. Membrane Switch. In the clinical field, membrane switches are important to gadgets such as diagnostic devices and patient monitoring systems, where their resilience and ease of cleaning are important for maintaining hygiene criteria. In the auto industry, these buttons are employed in control panel controls and infotainment systems, offering a sleek and modern interface for individuals.

Moreover, the customer electronics market advantages from membrane switches in appliances and portable devices, where portable design and user-friendly user interfaces enhance user experience. Industrial applications also leverage membrane layer changes for control panels in equipment and automation systems, emphasizing their robustness and resistance to harsh atmospheres.

In the aerospace and defense markets, membrane layer buttons are used in cabin controls and devices, where integrity and performance under extreme conditions are extremely important. Additionally, the gaming industry progressively includes membrane buttons in controllers and arcade equipments, adding to an appealing user experience. In general, the versatility of membrane layer switches over allows their prevalent usage check my reference throughout many markets, highlighting their importance in contemporary customer interface design.

Future Trends in Membrane Layer Switch Modern Technology

Additionally, using advanced materials, such as polycarbonate and polyester movies, is anticipated to rise, offering improved resilience and resistance to environmental stressors. These materials add to the overall long life of membrane layer switches, making them appropriate for harsher industrial applications.

In addition, the incorporation of wise innovation, including IoT connectivity, will certainly enable membrane layer switches to connect with other devices and systems, promoting an extra interactive user experience. This pattern straightens with the growing demand for smart gadgets across various sectors, from medical care to customer electronics.

Lastly, modification options are expected to broaden, enabling suppliers to develop bespoke solutions customized to details individual needs and preferences. These growths will position membrane layer buttons as essential elements in the development of user interface innovation.

Final Thought

In conclusion, membrane switches over stand for a crucial improvement in interface modern technology, offering a dependable and flexible solution for diverse electronic applications. Their split construction assists in small layout, while functions such as tactile responses enhance individual interaction. The sturdiness against environmental aspects even more strengthens their utility throughout numerous sectors. As advancements in material scientific research and touch sensing innovations proceed, the functionality and applicability of membrane Discover More layer buttons are anticipated to expand, reinforcing their value in contemporary electronic devices.

Report this page